page 22 of 33

<< Previous | Next >>

...

Transcript page 22

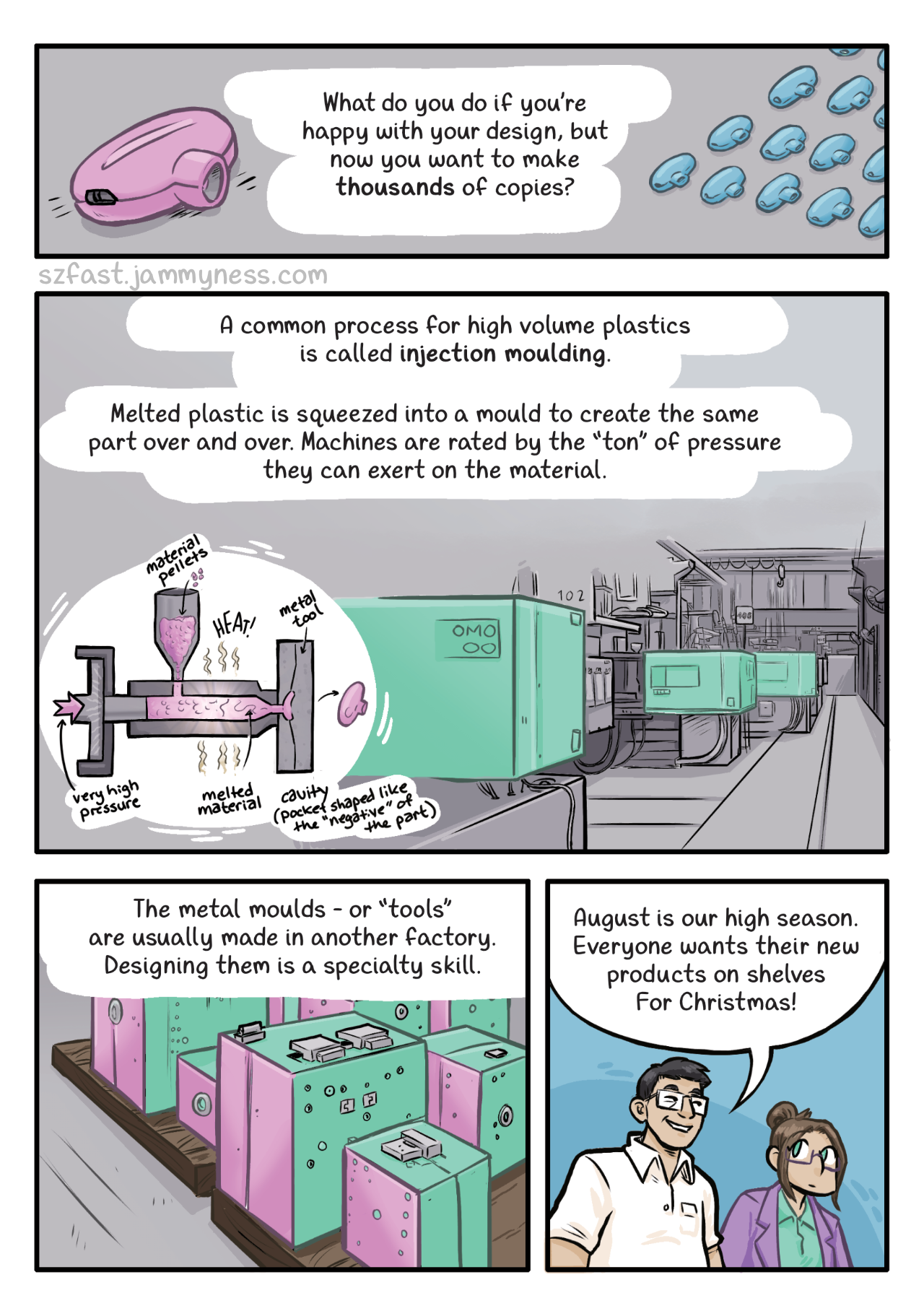

p1: The plastic enclosure is shown next to many rows of copies.

What do you do if you're happy with your design, but now you want to make thousands of copies?

p2: An industrial facility full of large machines. a diagram illustrates what's going on inside them: material pellets are melted and then squeezed into a small cavity using high pressure. The cavity is a pocket shaped like the "negative" of the part being created.

A common process for high volume plastics is called injection moulding. Melted plastic is squeezed into a mould to create the same part over and over. Machines are rated by the "ton" of pressure they can exert on the material.

p3: A row of large metal cubes that have many holes on them.

The metal moulds - or "tools" are usually made in another factory. Designing them is a specialty skill.

p4: Jam is listening to a worker from the injection moulding factory.

Worker: "August is our high season. Everyone wants their new products on shelves for Christmas!"

Back to home.