page 21 of 33

<< Previous | Next >>

...

Transcript page 21

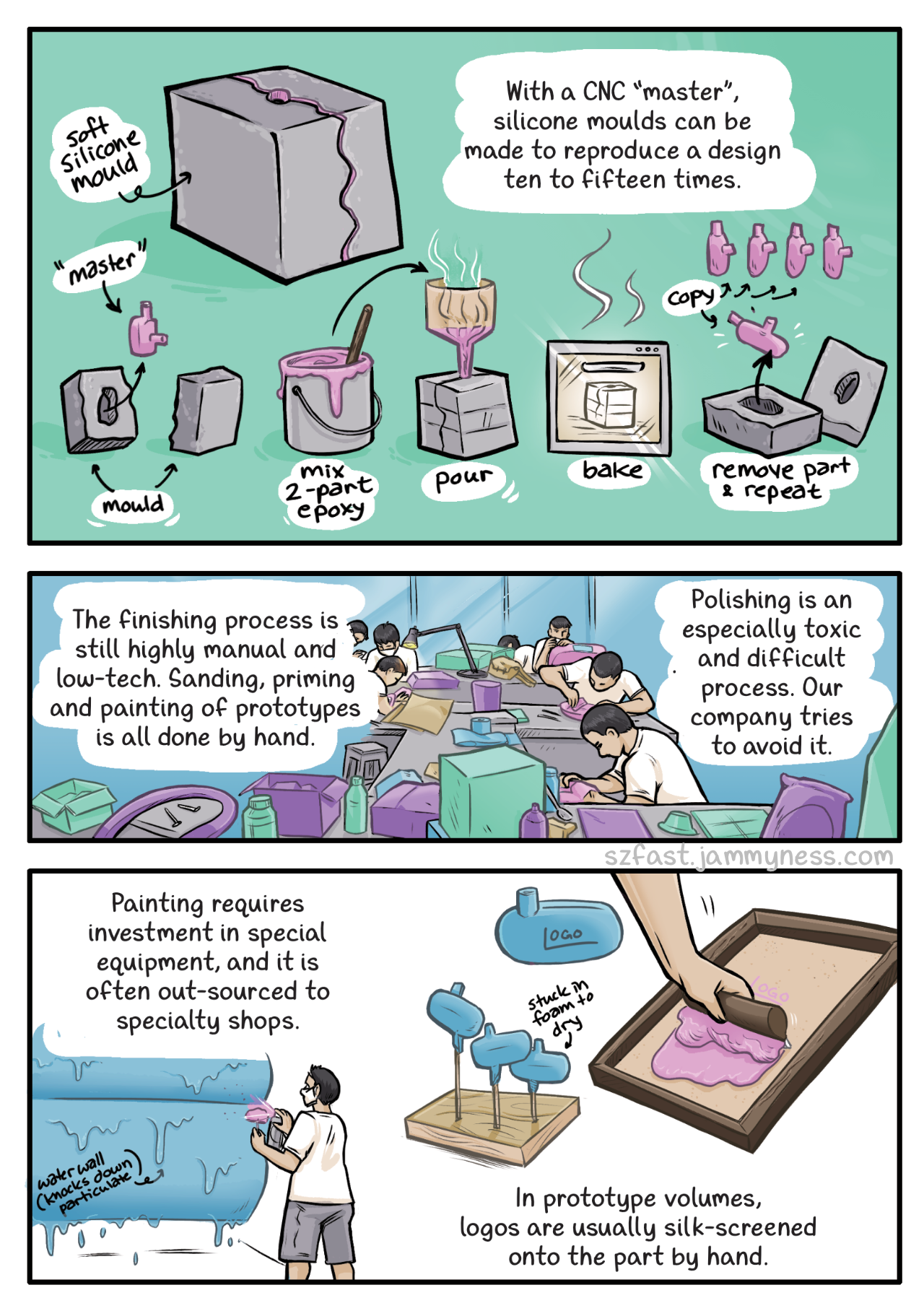

p1: A diagram showing the steps of silicone moulding.

With a CNC "master", silicone moulds can be made to reproduce a design ten to fifteen times. First a silicone mould is created by pouring silicone around the CNC master and curing it. The master is removed. 2-part epoxy is mixed in a pot and then poured into the mould. The whole thing is baked, and then the copy is removed. The process can be repeated.

p2: A large room with many workers. They are all working on different projects, sanding, polishing, painting. There are many parts, solvents and tools scattered around.

The finishing process is still highly manual and low-tech. Sanding, priming and painting of prototypes is all done by hand. Polishing is an especially toxi and difficult process. Our company tries to avoid it.

p3: A worker spraypaints a part on a stick. Behind the part is a water wall, which knocks down particulate. The prototypes on sticks are stuck in foam to try. A worker silkscreens a logo onto one of them.

Painting requires investment in special equipment, and it is often out-sourced to specialty shops. In prototype volumes, logos are usually silk-screened onto the part by hand.

Back to home.