page 18 of 33

<< Previous | Next >>

...

Transcript page 18

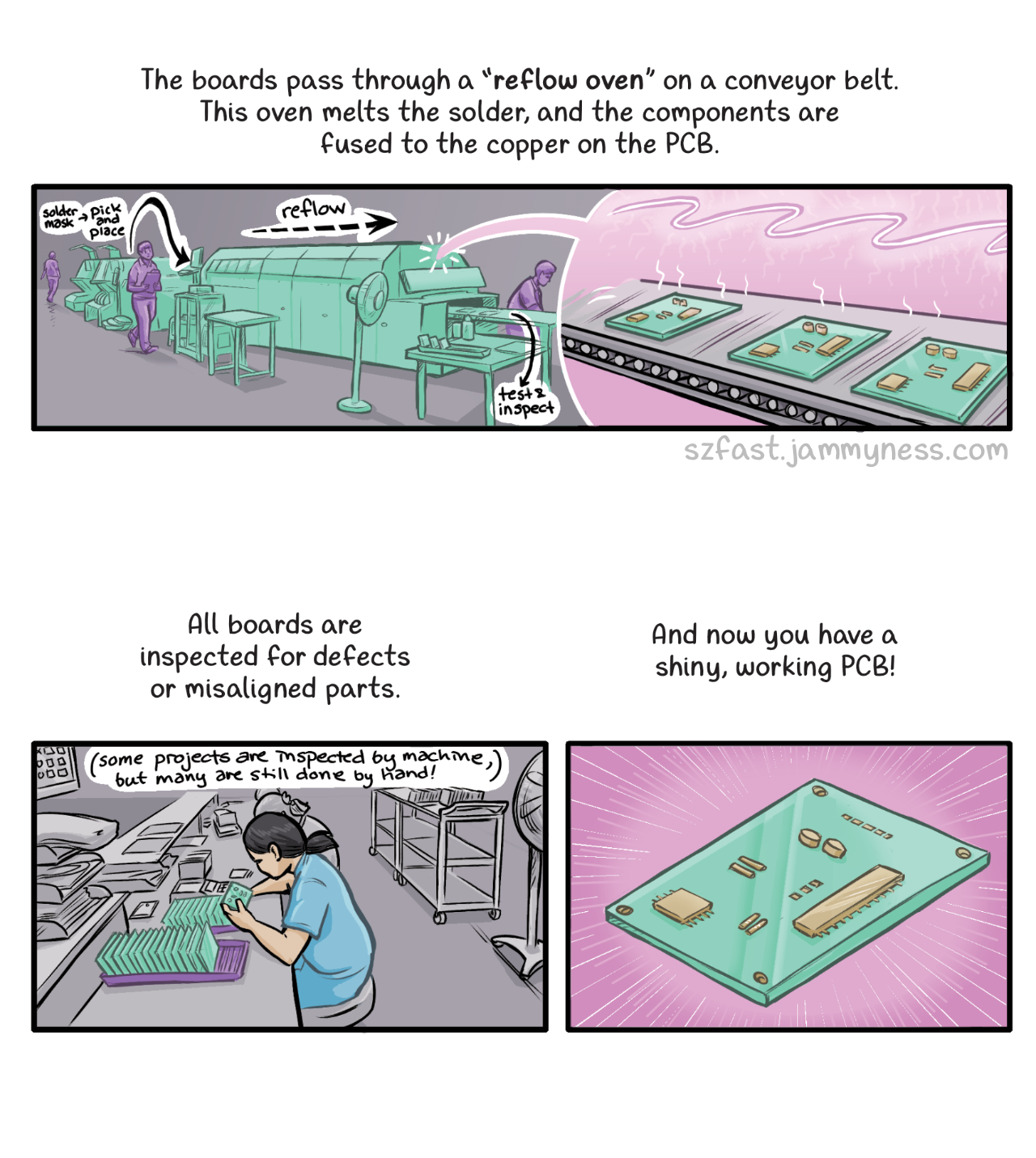

p1:A view of the PCB Assembly line. After the solder mask is applied and the pick and place puts the components on the boards, the boards pass through a "reflow oven" on a conveyor belt. The oven melts the solder, and the components are fused to the copper on the PCB.

p2: A worker inspects a row of completed PCBs.

All boards are inspected for defects or misaligned parts. Some projects are inspected by machine, but many are still done by hand!

p3: The finished PCB shines beautifully!

And now you have a shiny, working PCB!

Back to home.