page 17 of 33

<< Previous | Next >>

...

Transcript page 17

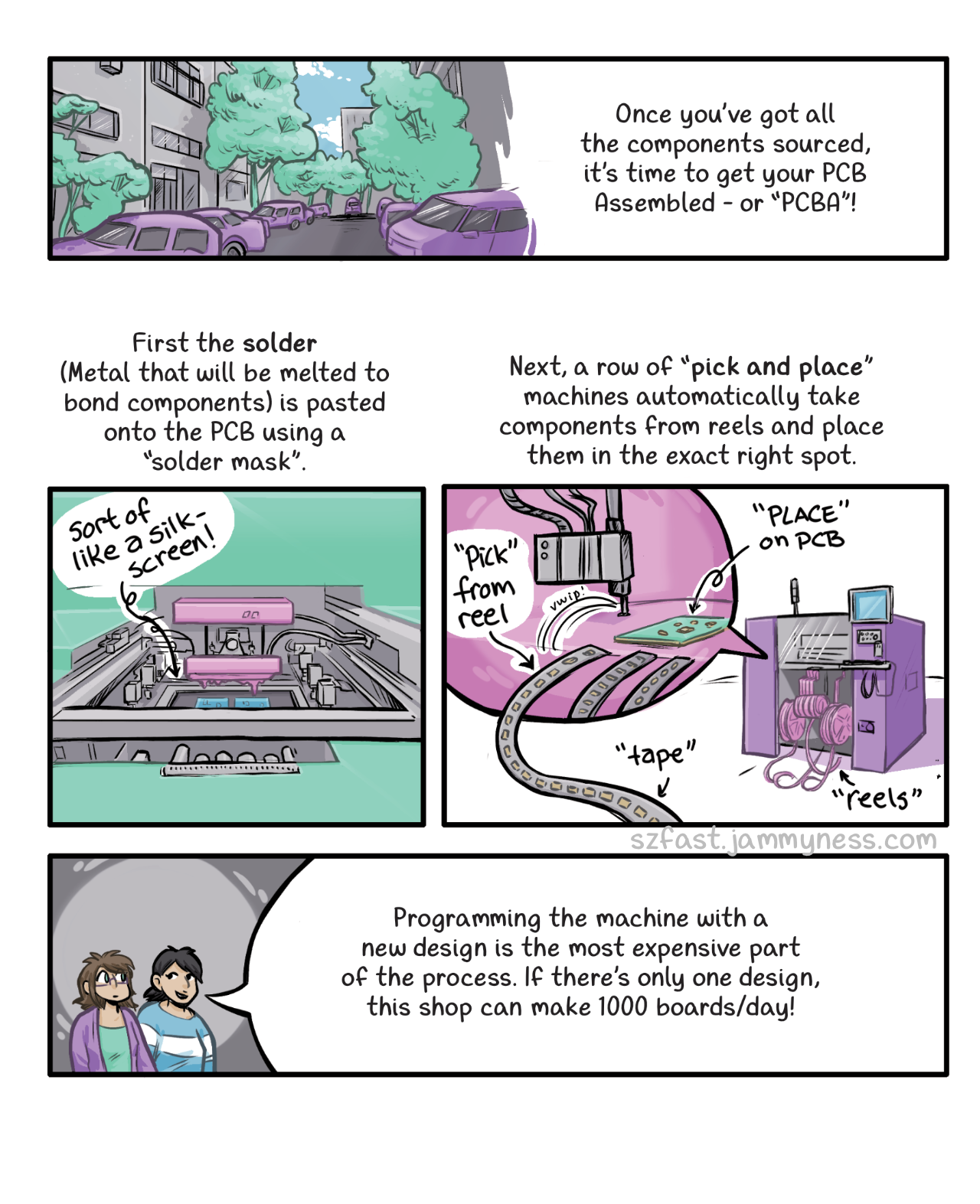

p1:The parking lot of another factory.

Once you've got all the components sourced, it's time to get your PCB Assembled - or "PCBA"!

p2: A solder pasting machine drips liquid solder past onto a screen with a template sitting below it. It's sort of like a silk-screen!

First the solder(Metal that will be melted to bond components) is pasted onto the PCB using a "solder mask".

p3: A pick and place machine - it looks like a large box with round "reels" stacked in the bottom. The reels store ribbons of individual components. The machine will "pick" individual components from this reel and "place" it onto the PCB inside the machine.

Next, a row of "pick and place" machines automatically take components from reels and place them in the exact right spot.

p4: Fiona explains the process to Jam.

Fiona: "Programming the machine with a new design is the most expensive part of the process. If there's only one design, this shop can make 1000 boards/day!

Back to home.