page 14 of 33

<< Previous | Next >>

...

Transcript page 14

p1: A worker uses a large machine with a high-powered camera to inspect PCBs.

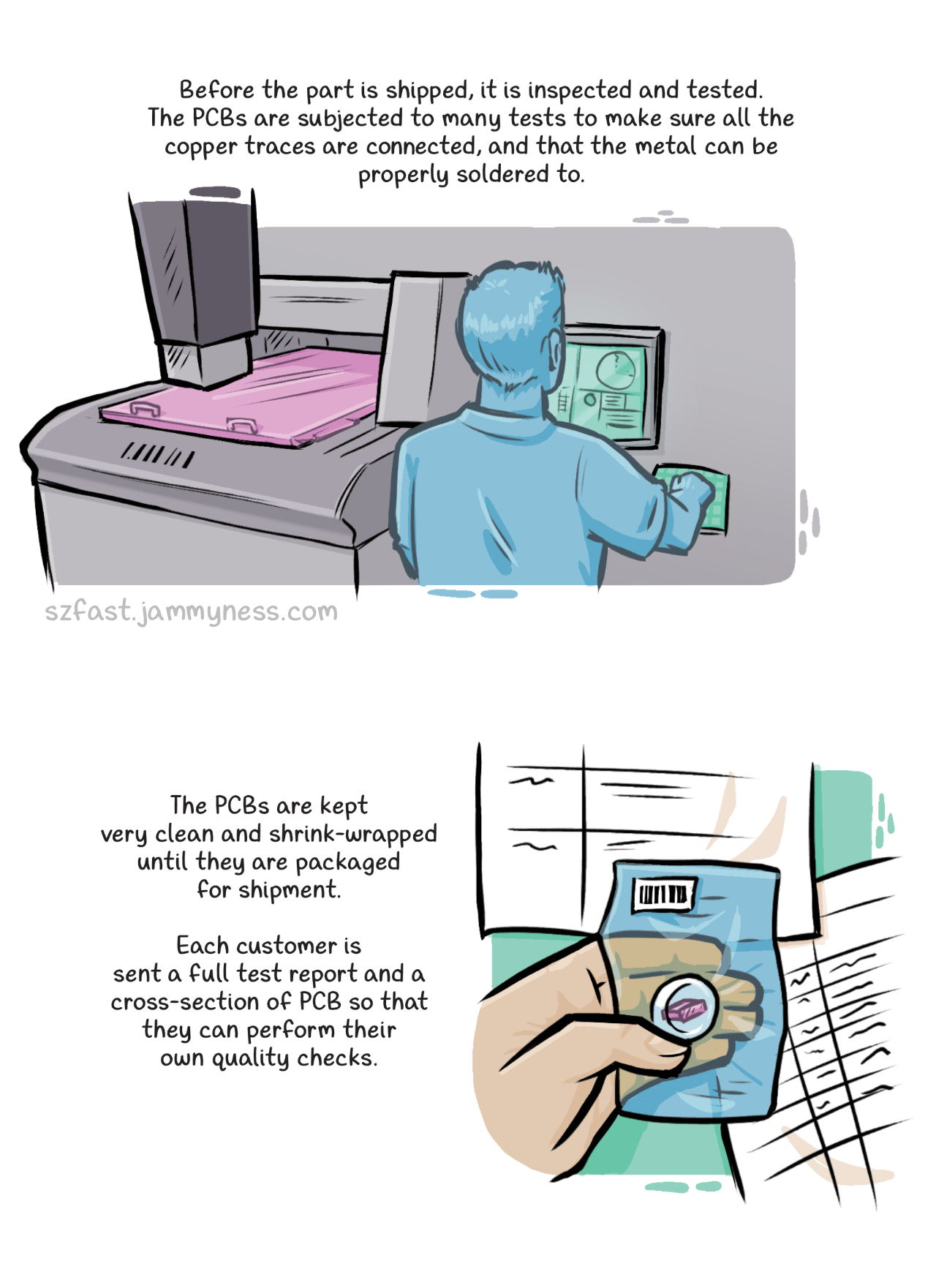

Before the part is shipped, it is inspected and tested. The PCBs are subjected to many tests to make sure all of the copper traces are connected, and that the metal can be properly soldered to.

p2: A worker holds a tiny piece of PCB that has been sliced off and suspended in a disc of resin. It's kept in a sealed plastic bag with a bar code. On the desk are test reports that have been competed.

The PCBs are kept very clean and shrink-wrapped until they are packaged for shipment. Each customer is sent a full test report and a cross-section of PCB so that they can perform their own quality checks.

Back to home.