page 13 of 33

<< Previous | Next >>

...

Transcript page 13

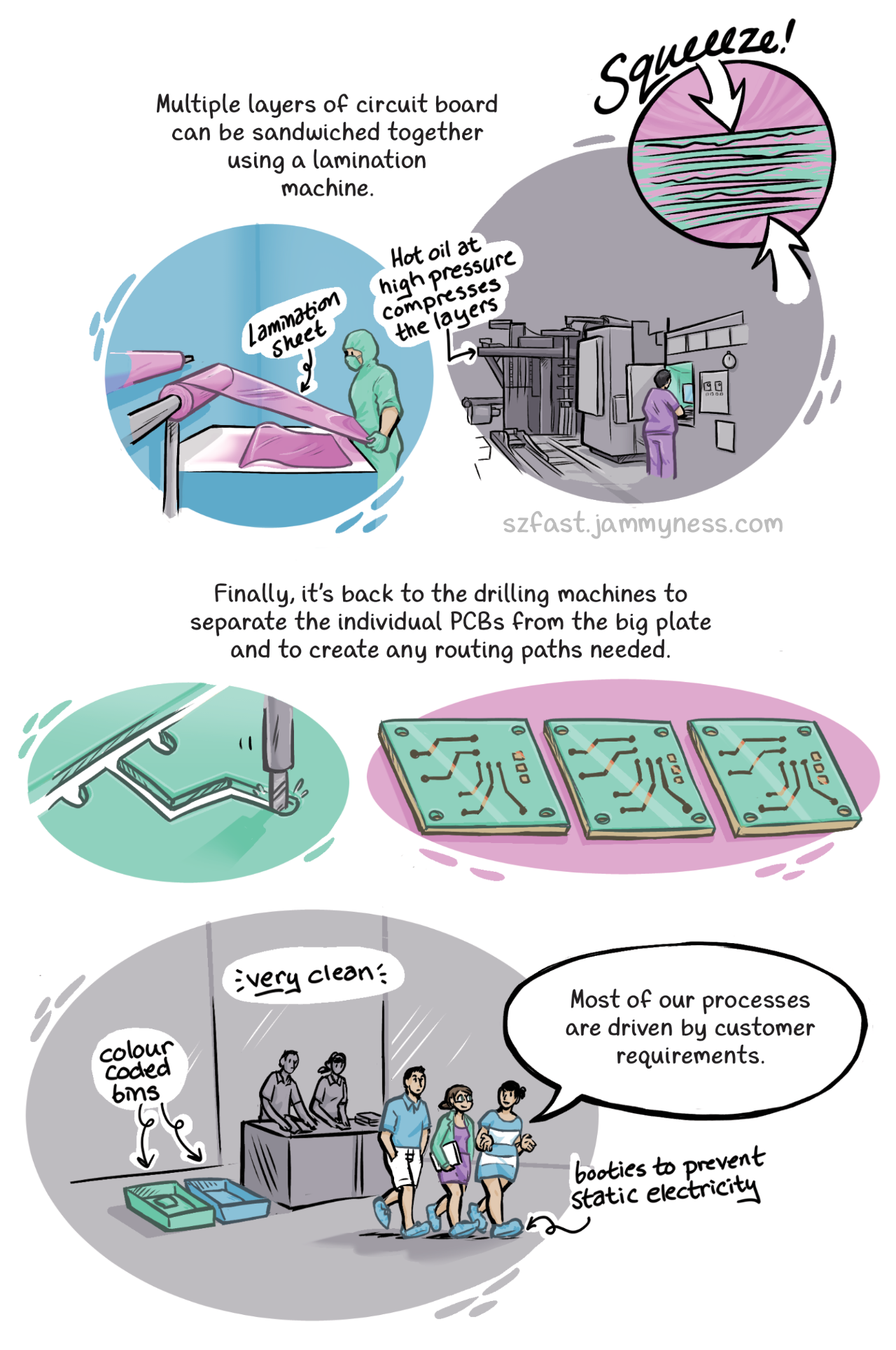

p1: A worker pulls a long thin layer of lamination sheet from a roll. This sheet is placed between layers of PCB. Another worker operates a lamination machine. With this machine, hot oil at high pressure is used to compress the layers together.

Multiple layers of circuit board can be sandwiched together using a lamination machine.

p2: A drilling machine carves a routing path through a PCB, and three individually-cut PCBs are shown next to it.

Finally, it's back to the drilling machines to separate the individual PCBs from the big plate, and to create any routing paths needed.

p3: Jam, Fiona and Phil walk through a tidy room where PCBs are organized. Two workers separate PCBs into colour-coded "accept" and "reject" bins, which are colour-coded. Everyone wears booties (thin fabric coverings) over their shoes to prevent static electricity.

Fiona: "Most of our processes are driven by customer requirements."

Back to home.